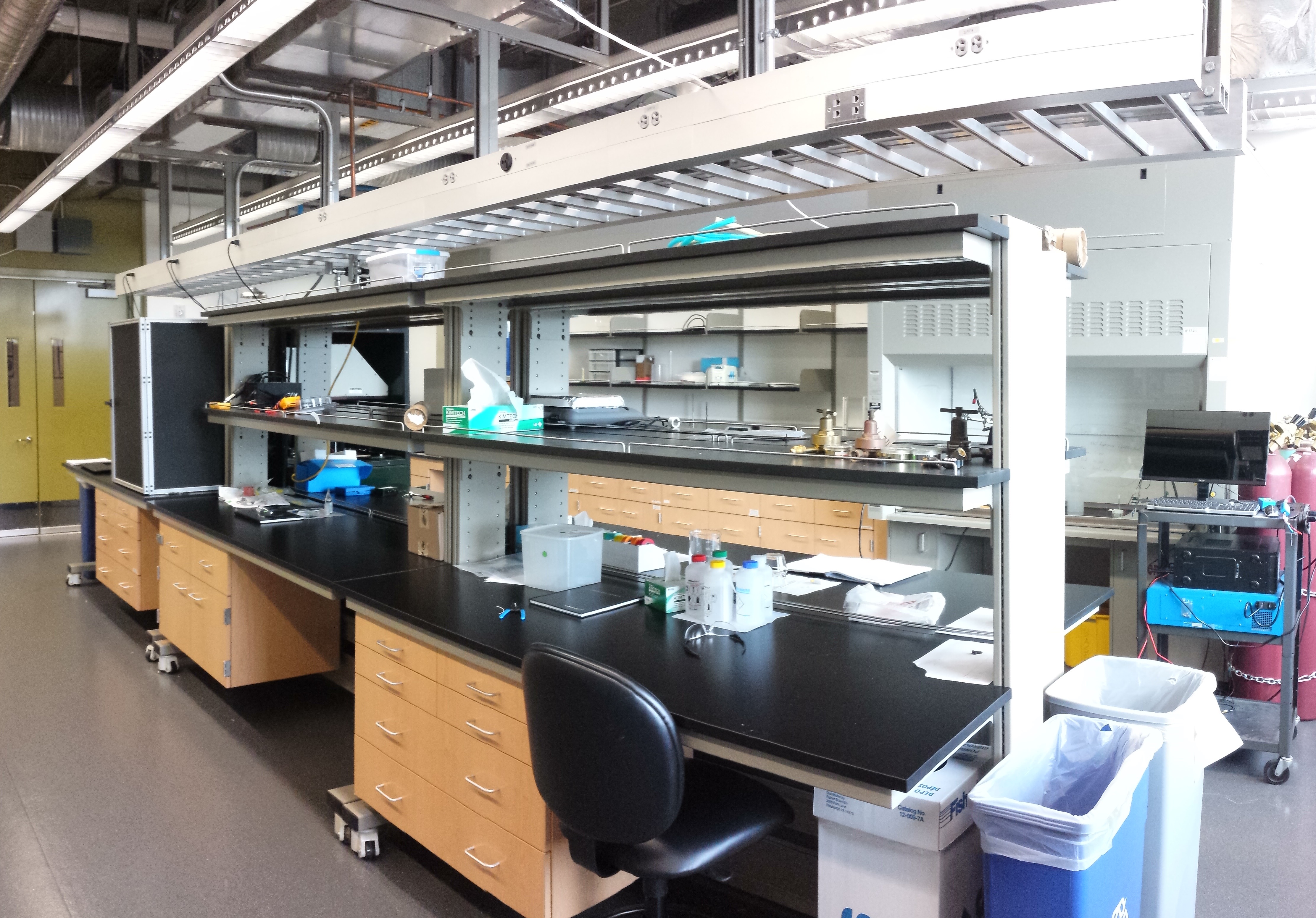

PI Fenning’s dedicated 795 sq. ft. laboratory is located in the Nanoengineering department at UC San Diego.

Relevant facilities for synthesis in the laboratory include:

- Temperature-controlled spin coater (MTI)

- Rotary evaporator (Buchi)

- Two wet chemical fume hoods

- 2 MW DI water system (Millipore Advantage A10)

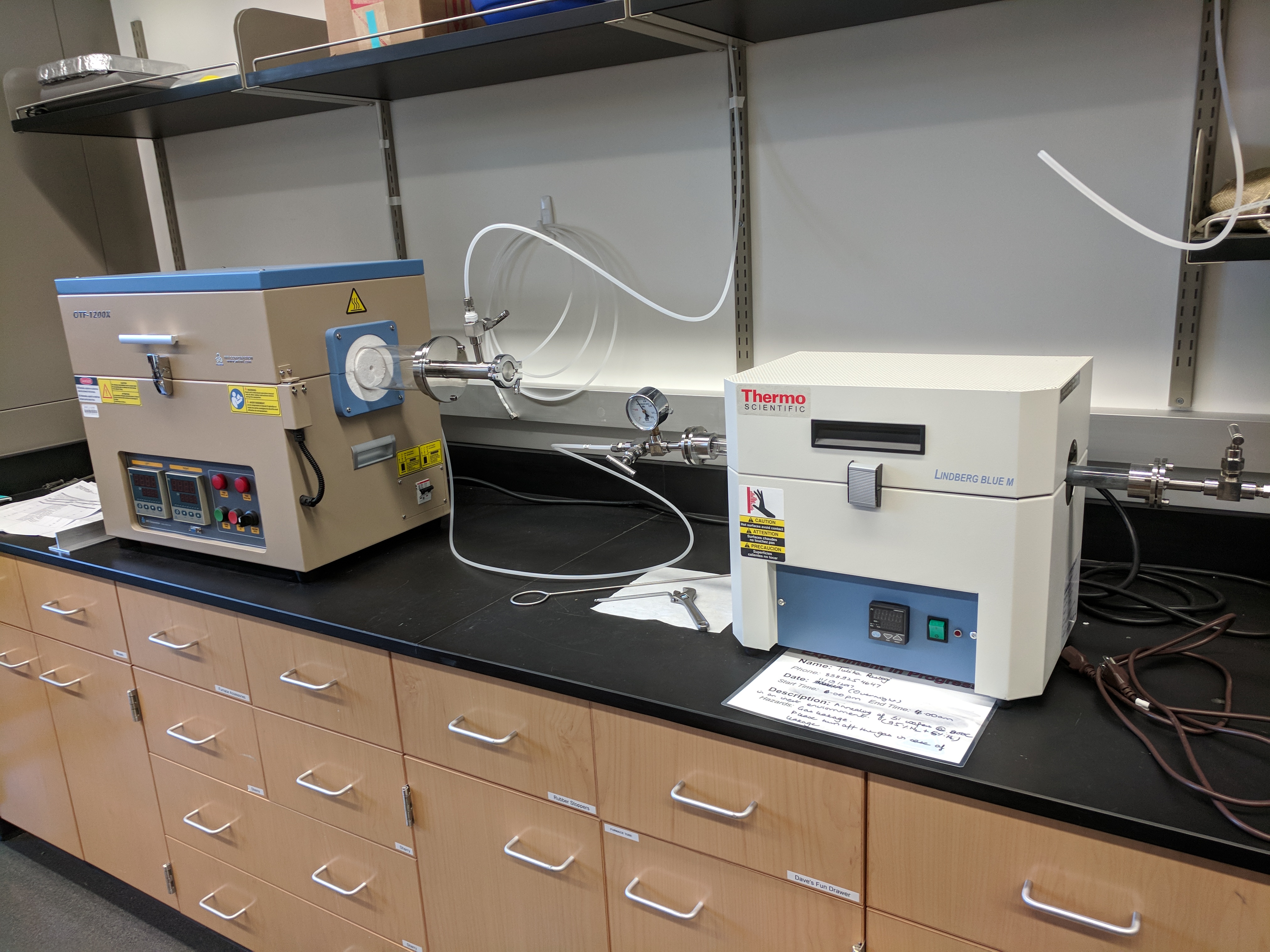

- 25” Dual Zone Tube Furnace with vacuum flanges (MTI)

- 1” Single Zone Tube Furnace with vacuum flanges (MTI)

- Glove box

Relevant characterization equipment includes:

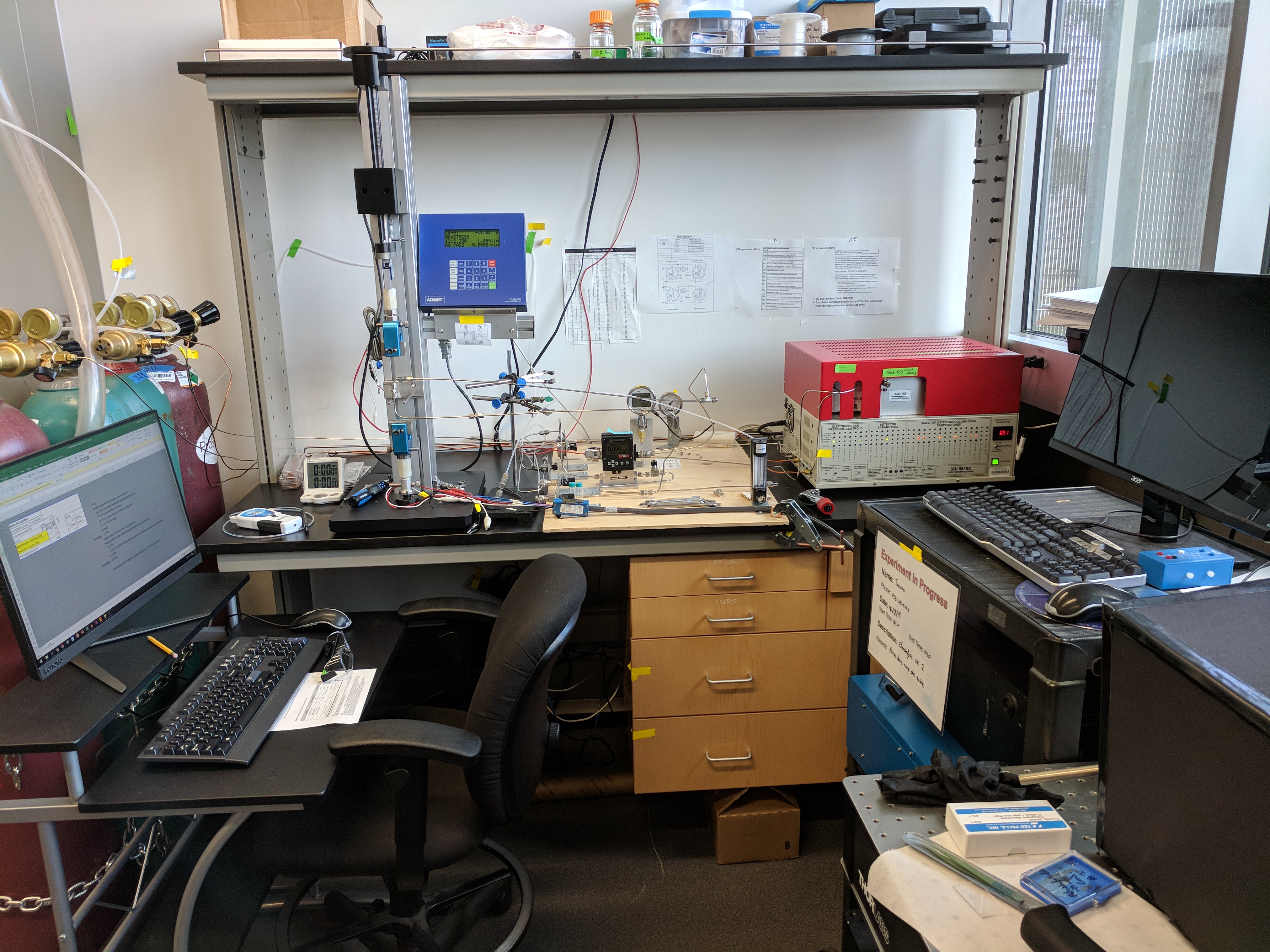

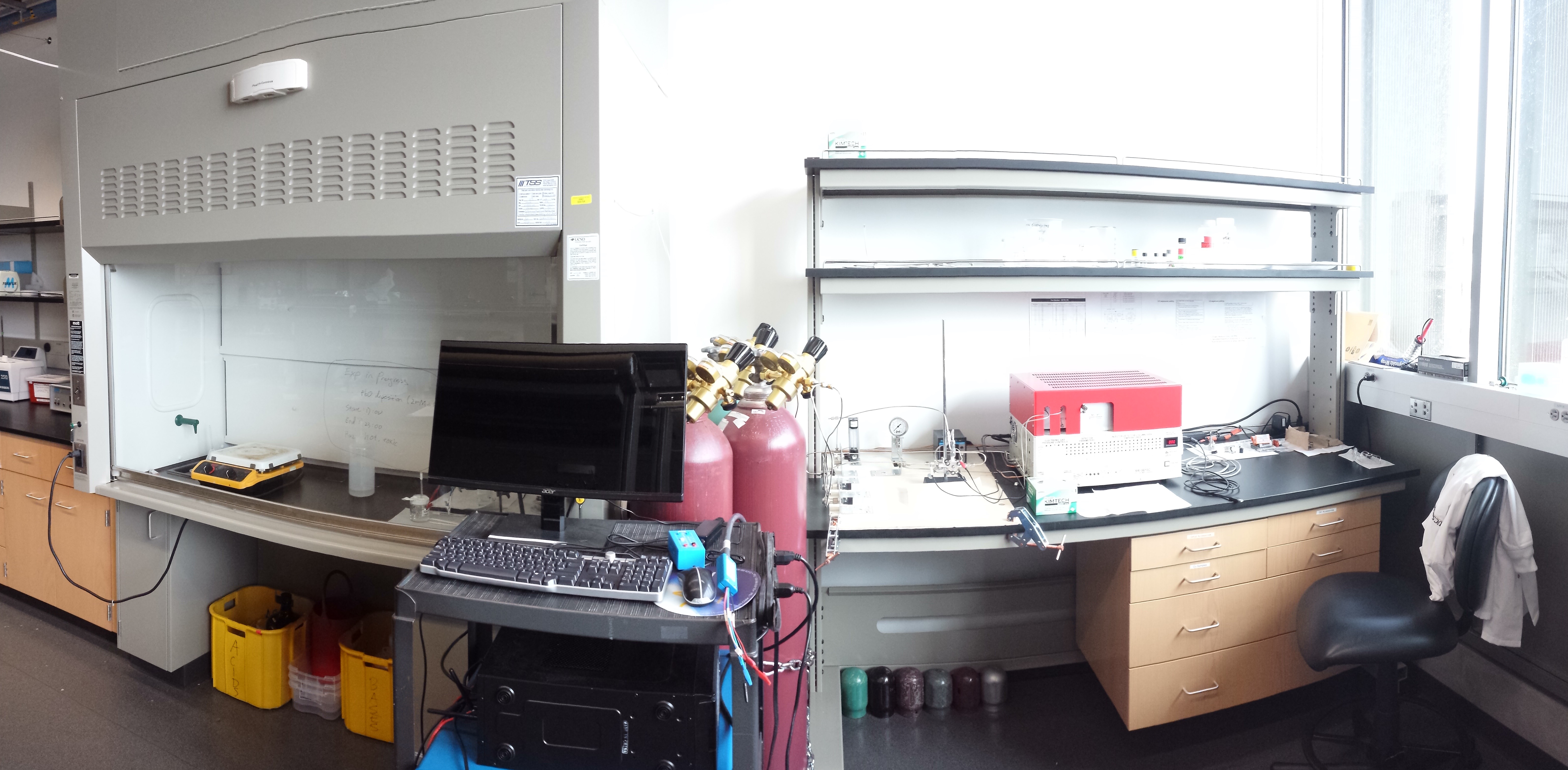

- Temperature-controlled I-V tester with Class A solar simulator (Newport)

- Light-/potential-biased QE measurement using a Cornerstone 260 monochromator optimized for 250-1800 nm and an SR830 lock in amplifier

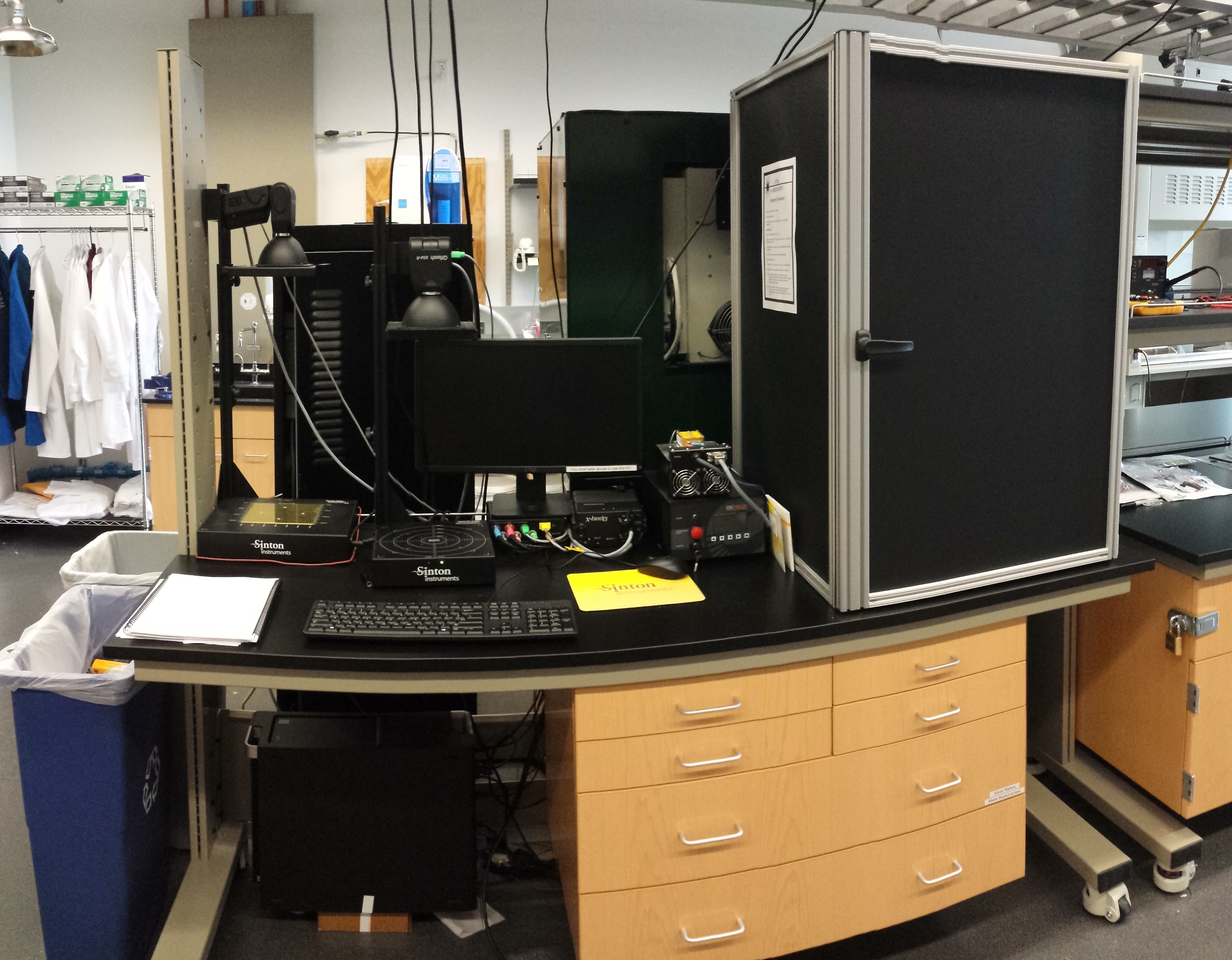

- Transient and quasi-steady-state photoconductance with submicrosecond resolution (Sinton Instruments)

- Illumination dependent Voc for assessing resistive losses in solar cells (Sinton Instruments)

- Photo- and electro-luminescence setup (under construction)

- Four-point probe (Signatone)

- 6-channel potentiostat with AC/DC capabilities for electrodeposition, capacitance-voltage and current-voltage measurement, and impedance analysis (Bio-logic)

- SRI GC with TCD and methanizer+FID for permanent gas and C1-C6 detection

- Customized electrochemical cell:

Optical (Lumerical) and device (Synopsys Sentaurus, PC1D) computational modeling is carried out on a dedicated workstation in the laboratory.

The Fenning Research Group leverages the 9,000 sf shared-use Materials Research Center in the UC San Diego Nanoengineering Department, equipped with:

- XRD

- UV-Visible spectroscopy

- Fourier Transform Infrared Spectroscopy

- Raman and µ-PL microscope

- Atomic force microscope

- SEM/electron backscatter diffraction

The on-campus cleanroom (Nano3, Calit2) contains 7,000 sf of Class-100 and Class-1000 space surrounded by 3,000 sf of analytical and design labs for materials characterization. Clean room equipment of particular relevance includes:

- Patterning: photolithography stations and mask aligners, sub 8-nm E-beam lithography (Vistec)

- PVD: DC and RF sputtering systems & multiple E-beam and thermal evaporators

- Thin film deposition: Beneq combined plasma- and thermal-atomic layer deposition tool, plasma-enhanced chemical vapor deposition tools, oxidation and diffusion furnaces.

The Nano3 characterization facility includes:

- SEM/EDS/E-beam induced current

- Scanning probe microscopes

- Dual-beam cryo-FIB (FEI) capable of removing selected areas for TEM and nano-XRF investigation with minimal implant damage at cryogenic temperatures.